Posted June 7, 2012 by Antonio Marku

New Swiss Turning Center Produces Miniature Medical Parts

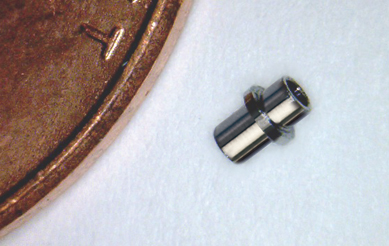

MEDWAY, MA — A new Swiss Turning Center added by MicroGroup machines medical parts down to 0.030 (0.762 mm) in diameter and in length, in tolerances of ±0.0002 inch, it was announced by Alex Magyar, Vice President Operations, here.

MEDWAY, MA — A new Swiss Turning Center added by MicroGroup machines medical parts down to 0.030 (0.762 mm) in diameter and in length, in tolerances of ±0.0002 inch, it was announced by Alex Magyar, Vice President Operations, here.

The “Tornos 7” machine brings to 20 the number of Swiss Turning Centers in production at the company, and allows machining of miniaturized parts utilized increasingly in advanced surgical instruments and medical implants, according to Magyar.

Unlike conventional “computer aided machining” or CAM in which the entire part is exposed while being turned, Swiss turning feeds the material through the collet variably, allowing tools to machine the part immediately adjacent to the collet, reducing deflection and improving dimensional tolerances significantly.

“Swiss machining allows the production of smaller parts with greater precision and efficiency than with conventional CAM, translating into higher quality parts at reduced cost for medical OEMs,” says Magyar, “including those requiring miniature components.”

The Tornos 7 turning center features five linear axes and two C-axes for machining components of simple to medium complexity at 20,000 RPM, and can be controlled to +/- 2 microns, allowing part tolerances of ±0.0002 inch (2 tenths). Up to 21 interchangeable tools can be set up at one time in any combination. The counter spindle is independent of, and equally as powerful as, the main spindle, allowing complete programming flexibility.

“Delivering smaller components with tighter tolerances more rapidly is consistent with MicroGroup’s commitment to expand and improve capabilities that keep our customers competitive,” says Bill Bergen, President.”