Custom Sizing & Shaping

MicroGroup, part of TE Connectivity, has comprehensive range of drawing, centerless grinding and straightening equipment can alter the OD, ID and/or wall thickness of tubing to achieve custom sizes that are not stocked while maintain short lead times.

Tube Drawing

MicroGroup tube forming/drawing equipment reduces the ID and OD of stock tubing to custom dimensions, and/or can increase its tensile strength through the reduction process. Custom tubing can be sourced almost instantly from over 7,000,000 feet (2,100,000 meters) of tubing in inventory, to meet your ID requirements from .005″ to 1″, with ID tolerances as low as ±.001″ on some larger sizes, and ±.0005″ on smaller hypodermic tube sizes. MicroGroup can draw any grade of stainless steel tubing from 302 to 455, and can also draw copper, nickel,  brass, Inconel® and other tubing.

brass, Inconel® and other tubing.

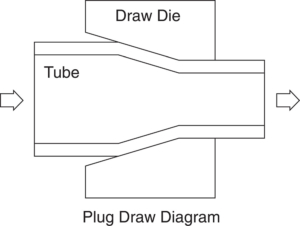

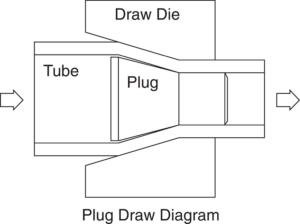

MicroGroup offers two methods of tube drawing (Sink Drawing and Plug Drawing) and has the ability to create custom shapes using these methods.

Sink Drawing reduces the diameter of a tube by pulling it through a die without the use of a mandrel. In sink drawing, the ID is determined by the OD and wall thickness of the pre-drawn tube. This is the fastest form of drawing, and suitable for drawing of thick walled tubing, as well as drawing of tubes smaller than .062″ OD where using a mandrel is not possible.

Plug Drawing uses an ID mandrel to shape the ID of the tube. This improves ID tolerance, and improves ID finish to as low as 32 RA (finer ID finishes can be achieved with ID Honing (contact sales for details). This process is slower and more expensive due to the need of precision design and manufacturing of the plug, and is limited to IDs larger than .062″.

Plug Drawing uses an ID mandrel to shape the ID of the tube. This improves ID tolerance, and improves ID finish to as low as 32 RA (finer ID finishes can be achieved with ID Honing (contact sales for details). This process is slower and more expensive due to the need of precision design and manufacturing of the plug, and is limited to IDs larger than .062″.

Shape draws: Using a combination of Sink and Plug drawing MicroGroup has the ability to precision draw material into different shapes and sizes of tubes, from ovals and rectangles to more exotic shapes. In the case of shaped draws, the mandrel supports the ID to allow for sharper ID corners that would not be achievable using Sink Drawing alone.

Centerless Grinding

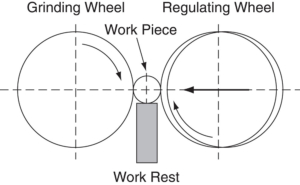

Centerless Grinding is so named because it removes material without the use of a spindle. Centerless grinding is accomplished by placing the tubing or rod on a work rest that positions it between a regulating wheel that spins the stock in one direction, and a grinding wheel that spins in the opposite direction. By varying the distance between the wheels, highly accurate outside diameters and improved circularity can be achieved.

Centerless Ground material can offer tolerances as tight as ±.0001″, and wall thicknesses as small as .0015″, depending on raw material starting size and material composition. By employing different grit wheels and tube polishing, MicroGroup can also offer OD surface finish as smooth as 6 RA.

Centerless Ground material can offer tolerances as tight as ±.0001″, and wall thicknesses as small as .0015″, depending on raw material starting size and material composition. By employing different grit wheels and tube polishing, MicroGroup can also offer OD surface finish as smooth as 6 RA.

Selecting standard ID sizes and grinding to the desired OD size can often be a cost effective approach to producing a custom sized tube, eliminating the higher cost of set-up charges and minimums for redrawing.

Straightening

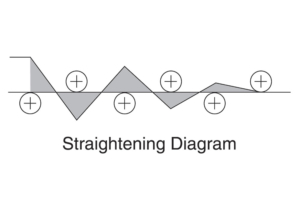

Utilizing six-roll straighteners, MicroGroup can straighten tubes to a minimum straightness of .001″ per inch and .010″ per foot.

Utilizing six-roll straighteners, MicroGroup can straighten tubes to a minimum straightness of .001″ per inch and .010″ per foot.

MicroGroup’s in-house Tooling Department can configure straightening rollers on a custom basis to straighten any size tube from 1″ to .010″, including custom shaped tubes.