Electrical Discharge Machining (EDM)

Electrical Discharge Machining (EDM) is ideal for intricate burr-free cutting of intricate contours or cavities in hard materials, eliminating the need to soften the material before machining, and then re-harden it through heat-treating. The process can be used with stainless steel or other electrically conductive materials including titanium, Hastelloy®, Inconel®, nitinol and Kovar®.

Also called “spark machining,” “spark eroding,” “burning,” “die sinking,” and “wire erosion,” the process uses electrical discharges between an electrode (the cutting tool) and the work piece, both immersed in a dielectric liquid (typically deionized water or dielectric oil), to remove material from the part.

Also called “spark machining,” “spark eroding,” “burning,” “die sinking,” and “wire erosion,” the process uses electrical discharges between an electrode (the cutting tool) and the work piece, both immersed in a dielectric liquid (typically deionized water or dielectric oil), to remove material from the part.

EDM offers consistent results and is particularly suited for parts requiring tight tolerances. Extra fine surface finishes can be obtained and near perfect perpendicularity achieved using EDM.

MicroGroup has proprietary fixtures, which permit the cutting of extremely small diameters (down to Ø0.001″) and to very short lengths (<0.005″). EDM cutting can produce edges with minimal edge break which may be desired for welding or other joining applications.

MicroGroup offers both main types of EDM as follows:

Wire EDM

Wire EDM uses a single-strand wire (typically brass) that is fed through the work piece to perform the cutting. The gap between the electrode and the workpiece is typically flushed with deionized water. This is a highly repeatable and consistent process that is excellent for exact lengths and other tight tolerances.

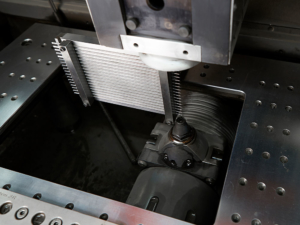

Sinker EDM

(also known as RAM EDM, Cavity EDM, Volume EDM or Conventional EDM)

Instead of using a wire as the electrode, Sinker EDM uses a graphite electrode, which is the negative shape of the feature being produced, to remove material as it “sinks” into the part. Also unlike Wire EDM, Sinker EDM need not cut completely through the part. These characteristics make Sinker EDM ideally suited to machining of burr-free holes, slots, or complex shapes in bar, tube or flat stock.

Sinker EDM uses a dielectric oil to control the rate of burning and to flush debris away to prevent arcing out. Since the electrode will wear as parts are burned it will require re-machining over time.

EDM offers numerous advantages over traditional machining methods:

- EDM can be used on any electrically conductive material regardless of alloy or hardness, allowing for easy cutting and machining of materials, which are difficult to machine traditionally. Such alloys include, but are not limited to:

- Nitinol

- Titanium

- Hastelloy®

- Inconel®

- Kovar®

- Since the electrode never actually contacts the work piece, EDM imparts no mechanical forces. This means that thin-walled or otherwise fragile parts can be worked on with no concerns about deforming or otherwise damaging the part. There is also no concern about galling from material buildup as on a traditional cutting tool.

- EDM cuts (wire EDM) and burned (Sinker EDM) features are burr-free, eliminating the need for potentially costly and time-consuming secondary deburring operations.

- Machining of electrodes (Sinker EDM) is typically more economical, and faster to accomplish, than purchasing of customized tooling. MicroGroup’s EDM Department utilizes its CNC machining, CAD/CAM capabilities and operator expertise to most effectively design and machine electrodes for maximum use and economy.

- CNC-controlled machines allow for intricate contours and complex feature geometry, and also ensure that processes are accurate and repeatable. Precision can be held to ±.001″ for most Wire EDM and Sinker EDM applications. Tolerances of ±.002″ are achievable for Sinker EDM applications with more complex geometries.